Amaze your friends with quadrilateral and rising dovetails.

Pages: 38-39

Issue #193, November 2011.

An ordinary day in the shop, but suddenly, youre dovetailing through another dimension, a dimension not only of sight and sound, but of mind. You are on a journey to a woodworking paradise whose borders are only limited by your imagination. This is the signpost, your next stop will be The Impossibles Zone!

Quadratail layout. Start with two pieces of contrasting stock, truly square and equally thick all about. Mark the length of the dovetails (perhaps three-quarters of the thickness) around the ends of both pieces with a marking gauge fenced against the end grain. Place dovetails on each side. Make sure they are exactly the same by using a marking gauge to trace the edges of the dovetails. Then reset the gauge to mark all the narrow ends.

We accept the limitations that dovetails have in the normal world. Although they are strong in all directions, dovetails can still be pulled apart in the same way they were assembled. Deviant woodworkers began to search for dovetails that would interlock indefinitely, so that solid wood can be faced in all directions. They created dovetails that can never be separated. Problem is, they can also never go together.

Quadratail cuts. Draw diagonal lines across both the ends of the pieces connecting dovetails. Mark the waste pieces and cut the sockets and tails. You will need to have the proper clearance with a fine saw that runs along the layout lines. You can easily saw the shoulders off the outside of the dovetailed piece, but the space between them and in the sockets on the other piece will need roughing in with a coping saw. Finish the end grain with your sharpest chisel.

Or so it seems. Welcome to the world of impossitails joints that exploit our tendency to think at right angles to create the illusion of impossibility. Take a look at the quadratail, and the rising dovetail. They are both locked with the key to imagination.

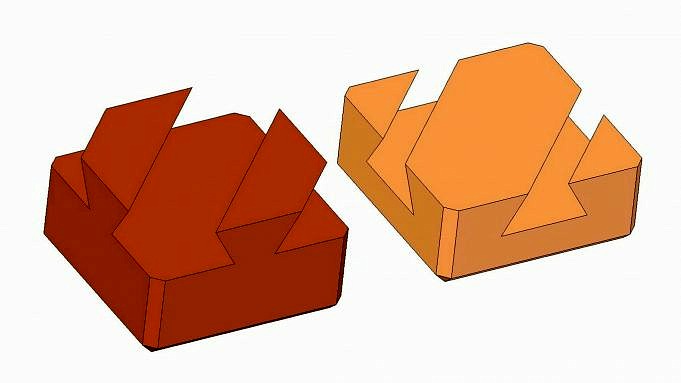

The Quadratail

is a sliding dovetail scarf joint that connects two lengths of square stock with dovetails showing on all four faces. Now, a dovetail emerging on two opposing faces would make sense; you could just slide them together. But four? But four?

The trick is that dovetails are connected obliquely through corners instead of directly across. Because the diagonal paths of the two sliding dovetails are parallel, the joint easily slides together and apart, but only at 45 to the faces.

The rising dovetail should be measured. The two pieces should be superimposed as if they were pressed together into a T. Place the widths of the pieces on one another and then draw the lines around. Starting on the piece that you will tenon, gauge down half of the thickness on the end grain. Then mark the end and then use the same setting to mark the side to be mortised.

Creating the illusion calls for precise saw and chisel work, but its easy enough. Simply draw equal dovetails on all four faces then saw and chisel them out on the diagonal. One is the positive space, the other the negative space.

Convergent lines. Set your bevel gauge to a bold angle and draw two sets of convergent lines on the edges of the piece to be mortised two lines beginning at the ends of the half-of-the-thickness line and two lines on the opposite edge beginning at the bottom. The mortise is defined by connecting the ends of the lines above across the face. (You can see how the backside of your mortise is reflected in the face on the dovetail saw.

The Rising Dovetail

This is more annoying and much easier to explain than to fix. This is where you can create the illusion of a dovetail by showing an oblique slice from a triangular prism. This is called the rising dovetail, because the tenon slides up in the mortise and fills the dovetail-shaped area.

This is how puzzle mallets were created around the turn of the 20th century. You can find the article in the April 2012 issue Magazine. When used with equal-sized stock, this joint isn’t very strong. The only place where I have seen rising dovetail in furniture is in the teachers’ lectern at a Colonial Virginia plantation.

Transfer marks. Place the piece on the tenon’s face edgewise. You have now created the dovetail-tenon.

The T-shaped foot of the lectern that faces the students was joined with a rising dovetail, posing a perpetual question and the lesson that things are not always as we suppose them to be!

Cheek and shoulder. Saw the cheeks and shoulders of the dovetail tenon. Cut the mortise by making three saw cuts, two down the sides and one down the middle then chisel out the waste. As necessary, trim the mortise and then slide them together.

Some of the old books advise you to glue these impossitails together so that the secret may not be discovered. Id leave them loose so that others can enjoy the mystery. It all depends on how annoying you are. PWM

Roy is the host of The Woodwrights Shop, the longest-running woodworking show on television (now in its 31st season on PBS).

VIDEO: Watch episodes from Roys The Woodwrights Shop online.

WEB SITE: Take a class from Roy.

TO BUY: The Woodwrights Shop: A Practical Guide to Traditional Woodcraft.

IN OUR SHOP: The Woodwrights Guide to Working Wood with Edge and Wedge.

Issue #193, November 2011.

Get this issue now

Recommendations for Product

These are the tools and supplies we use every day in our shop. Although we may be compensated for sales made through our links, these products have been carefully chosen for their utility and quality.